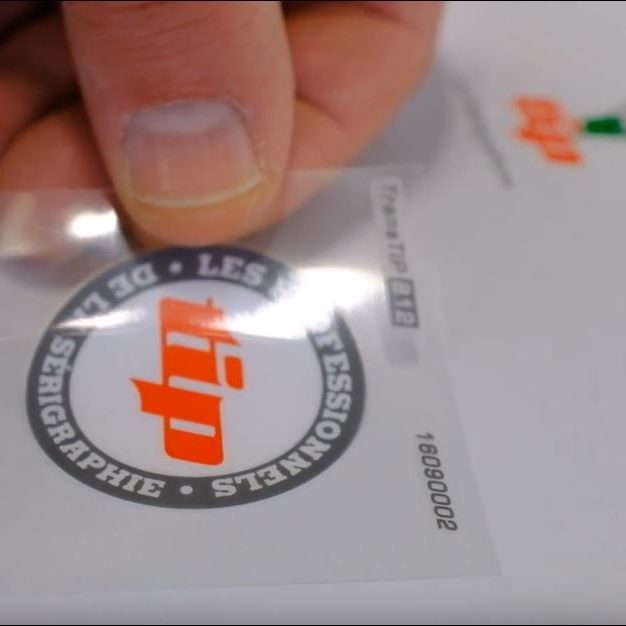

Dry transfer with TransTIP®

Dry decal is a technique that can be used To mark” on any substrate, apart from textiles.

TIP Sérigraphie, an expert in industrial printing and silk screen printing, tells you all about TransTIP®, a dry decal printing process that offers multiple technical advantages: heat resistance, chemical resistance and resistance to abrasion. Your industrial marking and by dry decal printing needs deserve the care of a specialist.

How does dry decal work?

Dry decal printing is carried out by silk screen or digital printing. It is a high-quality product with excellent longevity. It is also very easy to use and apply.

Dry decal explained

Dry decal is the equivalent of direct silk screen printing. In this technique, a very thin layer of ink is applied to your substrate by means of a complex of technical layers, colours and an adhesive. The ink is covered with a protective layer that guarantees its durability. Dry decal is a process by which an image or text is transferred without any background material.

Use and application

Dry transfers can be applied on many flat or curved, smooth or grained supports and you can mark many materials: metal, glass, ceramic, plexi, wood, carbon, plastic...

This type of marking is everywhere around you:

- on the frame of your bike

- on the fire extinguisher in the corridors of your office

- on your electric convectors

- on a boiler or heat pump

- on a spa or hot tub

- on paddles

- on a bow or arrows

- on a machine cover

- on an agricultural machine or an industrial sub-assembly etc.

Dry decals can be applied to many types of surfaces, flat or curved, smooth or grained, and can be used to mark a wide range of materials: metal, glass, ceramics, plexiglass, wood, carbon, plastic, etc. This type of printing can be found all around you: on the frame of your bicycle, the fire extinguisher in your office’s corridors, your electric convectors, a boiler or a heat pump, a spa or a hot tub, oars and paddles, a bow or arrows, a machine cover, an agricultural machine or an industrial sub-assembly, etc.

Applying a dry decal is very easy, just follow these steps:

- Prepare your substrate carefully: the surface you plan to mark must be clean and dry. Any dust, moisture, silicone agent or grease can affect the result

- Remove the white protection paper on the back of the print

- Apply the decal starting from one side and pressing firmly. Use a scraper to ensure that the print fits the surface perfectly

- Remove the transparent film carefully

The advantages of dry decal

Dry decal is often more appealing to the eye than direct printing. It is extremely thin, but adheres well and is very strong resilient.

- Resistance to low temperatures

- Heat resistance

- Damp Resistance

- UV resistance

- Abrasion resistance

- Resistance to rubbing, tearing or ripping

- Resistance to solvents, oils, hydrocarbons, chemicals and detergents

The use of dry decal enables you to shorten your production times, gain flexibility and gain autonomy. For instance, when it comes time to mark the covers of your machine tools, you can order your dry decals in advance and apply the graphic directly in your assembly line process, without interrupting production. The days of sending your covers to your screen-printing partner, then waiting for them to be printed and sent back to you are over, enabling you to gain valuable time. You save on the cost of transport between your production site and the screen-printing workshop, and also trim your carbon footprint. Last but not least, you keep control over printing responsibilities and involve your teams, by giving them the chance to step up their skills.

The use of dry decal enables you to shorten your production times, gain flexibility and gain autonomy. For instance, when it comes time to mark the covers of your machine tools, you can order your dry decals in advance and apply the graphic directly in your assembly line process, without interrupting production. The days of sending your covers to your screen-printing partner, then waiting for them to be printed and sent back to you are over, enabling you to gain valuable time. You save on the cost of transport between your production site and the screen-printing workshop, and also trim your carbon footprint. Last but not least, you keep control over printing responsibilities and involve your teams, by giving them the chance to step up their skills.

TransTIP® dry: 50 possibilities for industrial transfer marking

Choose Trans TIP® for your industrial printing needs. Our dry decals can be applied to all substrates and be used in all areas of industry: heat pumps, machine tools, kitchen equipment, engine sealing, etc. Using the TransTIP® technology developed by TIP Sérigraphie, your products look as though the graphic were embedded right into their material.

From our range of 50 decals solutions, we will find the one best-suited to your needs. We go over your marking project with you and take into account all the constraints arising from:

- The type of substrate you need to decorate, its material, colour, and finish.

- The conditions under which dry decal will be applied: who will do the decal application, under what conditions, at what pace and with what precision?

- Your substrate's environment (indoor or outdoor), its exposure to the weather and/or chemical attacks.

TIP Sérigraphie has developed its own request form according to detailed requirements called G.E.S.T (Gestion des Études Sérigraphique Tip). During your discussion with your regional sales and technical manager, you will fill out a detailed questionnaire which is then sent to our method and development department. Using these answers, we will be able to recommend the decal printing option that is just right for your needs.